Can the magnetic flap level gauge completely replace the glass plate type level gauge?

Both the glass plate level gauge and the magnetic flap level gauge can observe the liquid level, but there are still differences in the details of the use. First of all, the glass plate level gauge was originally designed for use in the boiler industry, and some people called it a reflex glass/transparent glass level gauge. But with the development of society, it can no longer meet people's observation needs, and it is also difficult to use in some occasions.

For the mid-range of the glass plate level gauge, the actual level cannot be observed. For example, the range we ordered is 450mm, but the actual level we observed is only about 300mm, which creates a blind zone, and of course there are observation errors. Causes deviations in people's vision. And most of the current working conditions need to transmit signals to the control room, but also realize various functions such as high and low alarms, so that the glass plate level gauge cannot be realized. The magnetic flap is a rapidly developing product in recent years. It quickly replaced glass plates and glass tubes in various industries. Because of its powerful functions, it can be adapted to the needs of various working conditions, so that the entire liquid level control process can be realized. Intelligent. Greatly save manpower and financial resources.

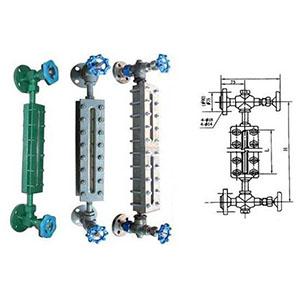

The magnetic flap level gauge observes intuitively, the liquid level display is accurate, there is basically no blind zone, and the range can be observed as much as possible. However, compared to the glass plate level, the price of the magnetic flap level gauge is higher. Due to the complex structure and the relatively high failure rate, the glass plate level gauge is still widely used because of its low price and high reliability in world-wide.