Description

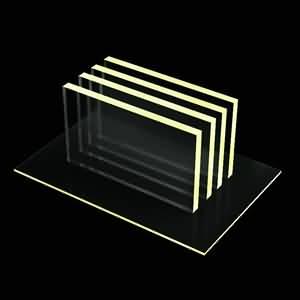

Sight glasses are used in piping systems where it is necessary to observe the product flow. Sight glass allow operators to observe the fluid flow direction, approximate rate of flow and condition of process fluids. Sight glasses should be designed to provide clear, continuous and unobstructed visibility of processes or products in piping, tanks or vessels.

Sight Glass is designed to application request,accommodate various mounting positions, fluid characteristics, flow rates and directions, there are several normal types sight glass as follows:

- 1. Plain Type Sight Glass - May be installed in any position to observe fluid flow in any direction. These style indicators are usually employed to detect either the presence or absence of solutions, or to observe fluids for turbulence, color or clarity.

- 2.Tubular Type Sight Glass- This style is well suited for vertical lines with downward flow direction. These units are particularly recommended for applications characterized by low or intermittent flow rates, such as distillation processes.

- 3. Flapper Type Sight Glass- Recommended for monitoring either horizontal or vertical lines with upward flow. The flapper position indicates current flow rate. Flapper style indicators are the appropriate choice for use with clear and semi-opaque solutions.

- 4. Impeller Type Sight Glass- This style indicator may be installed in any position to indicate flow in any direction. The visibility of rotor motion makes this style particularly well-suited for monitoring clear, translucent or dark solutions.

- 5. Anti-corrosion type Sight Glass: It’s suitable for acid, alkali and many organic solvents. It use PTFE lined stainless steel, PPR, PVC as body material.

Main Application of sight glass

- Analyze fluid quality (ex. color)

- Analyze fluid levels

- Analyze amount of contaminants

- Analyze size of contaminants

- Analyze type of contaminants

- Analyze fluid flow of medium

|

Drift diameter |

1/2"- 4", |

|

Material |

Stainless Steel 304, 316L, |

|

SealingGasket |

NBR, EPDM, SILICON, VITON,PTFE, FPM |

|

Surface treatment |

180~420Grit or unpolished |

|

Connection mode |

Threaded NPT |

|

Standard |

ISO, DIN, IDF, SMS |

|

Application |

Pharmacy, beer, food, dairy, beverage, cosmetic, chemical industry |

|

OEM and Customized |

According to the order quantity,Negotiable |